|

|

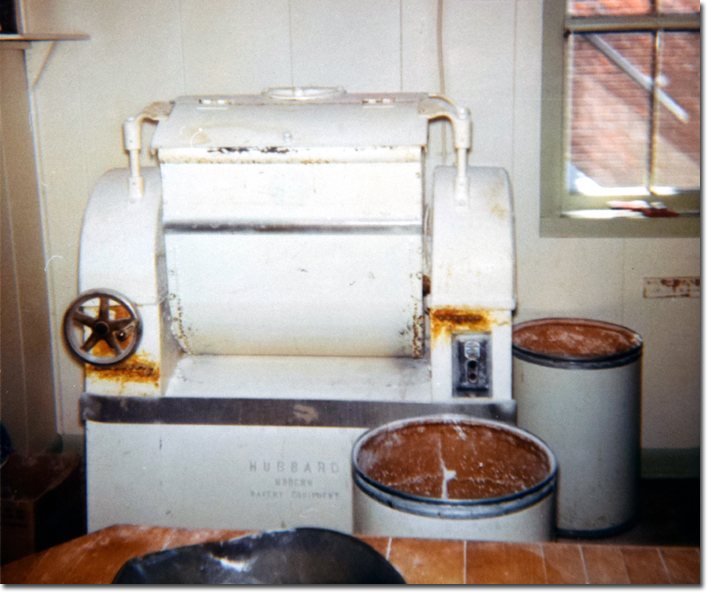

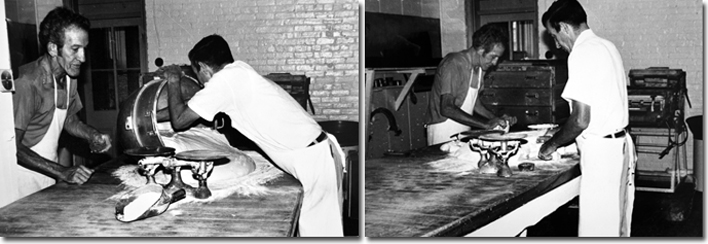

The process of producing the daily batch of white bread began very early in the morning when Bill would get up before the sun and go downstairs and mix the dough in this ancient but very effective bread mixer. Inside were two thick iron arm rotating steadily and endlessly (at the time I thought I seemed to quite often get the job of cleaning the inside of the mixer which had all kinds of little knooks and crannies!).

Into this mixer would go a full hundred pound bag of white flour, along with a pound of 12 oz. cake yeast, 12 oz. salt, 12 oz. sugar, 12 oz lard, 12 oz reddi sponge, 1/4 scoop of whey powder and 1 pais of water. The temperature of the flour and the water were critical in order to ensure efficient fermentation.

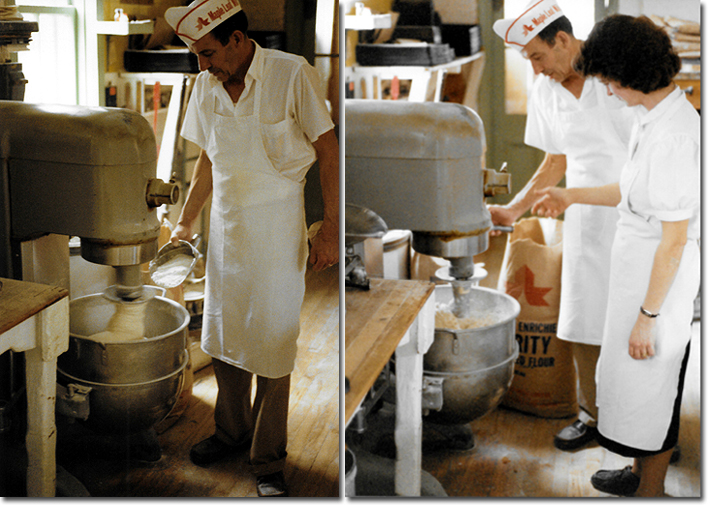

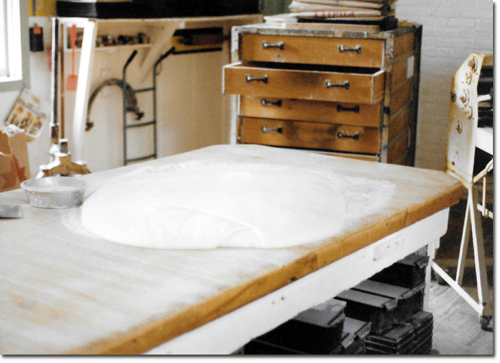

After mixing, and kneading, the dough would be carved into huge slabs and transferred to the long work bench in the middle of the shop, dusted with flour and covered with a large sheet of plastic while the magic took place and the dough came alive.

As hard as this part of the process was, it was a breeze compared to what it was way back when the bread was mixed by hand in a bread trough. I can't imagine what kind of arms those boys had!

The crank on the front of the mixer on the left was used to tilt the tub of the mixer forward to facilitate the removal of the dough. On the right was a simple on and off switch; only one speed. On either side of the mixer, beside the crank and the switch are lubrication ports to keep things running smoothly in the gears on either side.

|

|

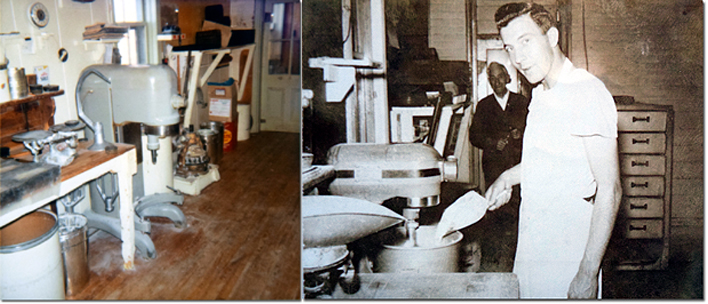

Smaller batches products like rye bread or 6-grain bread, cookies, bran muffins, etc. were mixed in the stand mixer. There were two sizes of bowls and different hooks. Much like today's kitchen counter-top mixers, there were several speeds. In this model, the bowl would be raised and lowered into position for mixing.

The top left photograph was taken in 1970s while the photograph on the top right with Ambrose Pilon adding flour to the mix and L.V. Pilon looking on, was taken in 1956.

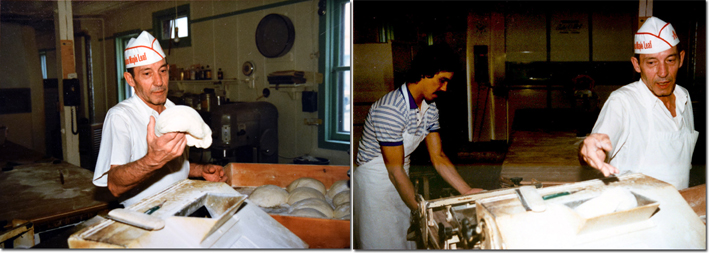

The bottom two pictures were taken on Pilon's Bakery's last day, May 15, 1985.

Nothing had really changed except the people.

|

|

The dough that was mixed in the stand mixer could be left to rise in the mixing bowl or placed on the bench. Once ready, it was cut into pieces of a certain weight, depending on the product. These pieces are then kneaded into balls and placed in the drawers of the proofer that was against the wall beside the door to the front processing room.

For a small batch like the ones being worked on in these photographs, this process might not take more than 15 minutes or so, but for a batch of white bread which was made of 144 loaves of bread, the process was long. While some of the banter between the brothers could be animated at times, there was also long periods of silence where the only sounds heard were the cutting of the dough, the clicking of the scales and the occasional popping of yeast bubbles as the dough was kneaded and shaped.

|

|

|

The first rise took place in the mixing bowl, for small batches, or on the work bench, for large batches. When scaled and shaped into balls, they were placed in the drawers of the wooden proofer to rise a second time before being shaped into loaves for the third and final rise in a metal proofer.

In the bottom of the metal proofer there was a small hotplate on which a metal container with water produced all important heat and humidity to help the loaves reach the optimal proof.

|

|

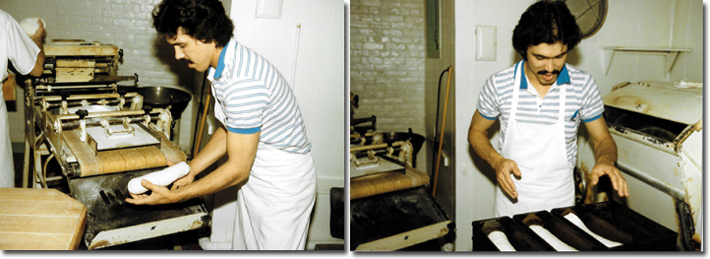

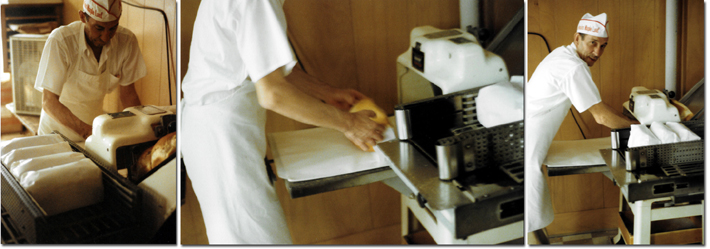

When the bread had proofed in the drawers it was time to shape the dough into loaves. There were two ways used to do this. The first was the old method of shaping by hand. This was in fact often done for smaller batches of specialty breads. But when faced with 144 loaves they turned to motorized help.

The proofed, dusted dough balls were fed into an opening at the top of the rear of the machine. Rollers with specific pressures would then roll, guide and shape the loaves which would emerge in a tray at the front of the paner as perfect dough cylinders ready for the final rising.

Of course, the person placing the rolled out loaves into the pans had to be on his toes in order to avoid dough jams! Lots of fun and always good banter.

|

|

The natural gas oven had six slowly revolving trays on which the baked goods were loaded. Various products required different temperatures and so the sequence of baking had to be planed to maximize the use of gas.

When not in use, all was quiet, but the tray could still be turned on. On more than one occasion, Bill demonstrated how it was possible to lie calmly on one's back and go on a ride! I tried it only once to be able to say I did it!

If you have a good eye, you'll recognize a couple Dutch-oven loaves going by the doors.

|

|

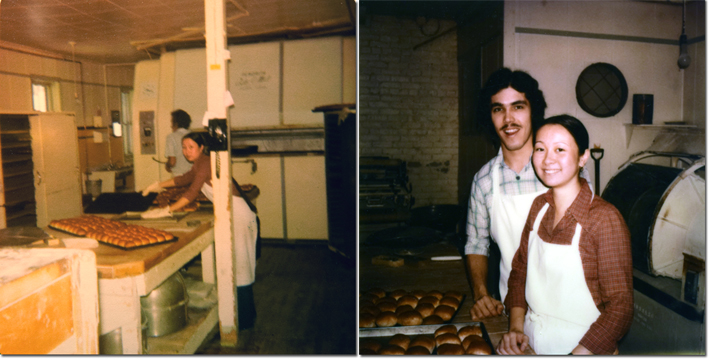

I spent a lot of time working in back of the bakery with my Dad and my Uncle as well as in front, helping out with clerking. When Abbie visited from Toronto, there was no question but that she had to give a hand at the shop as well!

While Abbie tried her hand at rolling buns, she was better at stacking them on trays for display in the store. All help was greatly appreciated and valued.

|

|

Everyday, at around 11 o'clock, the bread was taken out of the oven. The pans containing 4 loaves each would be flipped out onto the work bench. A cooling rack on wheels would have been brought in and the bread quickly placed on the shelves to begin cooling down. The rack would then be wheeled into the front processing room and a fan, made from a car's radiator propellor attached to an electric motor bolted to a wooden table, would be aimed at the rack and turned on. At the same time, the front door of the processing room was opened so that the warm air could escape. Coincidentally, this flooded Main Street with the enticing smell of fresh bread and people knew to come to the bakery.

Some bread would be sold still hot and only loosely wrapped in brown kraft paper. Trays would be loaded and placed on the counter so that people could chose the loaf they wanted. There was always the odd person who managed to give a loaf a squeeze and ask whether it was fresh. As if!

When the bread had cooled completely, most of the remaining plain white loaves would be sliced and wrapped. That was a slow and tedious job.

People would come from miles around, some as far as Montreal and Ottawa to buy the sliced Sony Boy loaves. We would use empty 100 pound flour bags to put 12 loaves of bread which were carted off in all directions, destined for freezers.

|

|

|

The shop was a really interesting social hub. When salesmen came to drop off orders to sign-up some new ones, there was always a visit with 'the boys' in the back. All kinds of topics would be discussed. Sometimes these exchanges would get quite heated but it was all in good fun. No topic was out of reach: politics, religion, whatever. Old friends and acquaintances also dropped in for the latest news or gossip. Some were occasional visitors and others were regulars, like Pat McManus. He had his spot beside the oven and even had a place in the shed for his 'things'.

Ambrose and Gisèle ended up having 13 grandchildren: a baker's dozen no less! Catlin was the only one of those grandchildren to ever come to the bakery and her visit was captured in this photograph of her with her parents Ray and Cheryl.

|